400-8016-802

中文版

Date:2020-12-7 Sources: Wenhui Author: Shi Bozhen Mouxin Pei Clicknum:508

Chang''e-5 lithium-ion battery replaces the higher-energy lithium cobalt oxide interconnect material and graphite titanate material, replaces high-molecular-weight binder materials, reduces the amount, and optimizes the pole piece formula to increase the active material content.

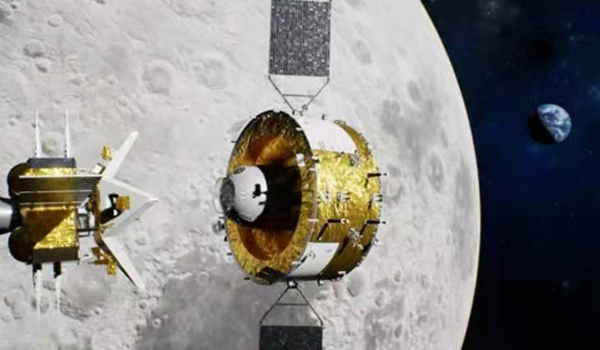

The power supply is an important support for the continuous operation of the spacecraft in the vast space. In the Chang''e-5 mission, the 811 Institute of the Eighth Academy of China Aerospace Science and Technology Corporation undertook the development of the orbiter, lander and ascender power products among the four platforms of lander, ascender, orbiter, and returner. The power system is composed of a power controller, a lithium-ion battery pack and a solar cell array. In order to ensure that the mission is guaranteed with the best performance, the developers of the 811 Institute of the Eighth Academy of China Aerospace Science and Technology Corporation have used enough horsepower. It has the highest domestic and international leadership, the highest specific energy for aerospace applications of lithium-ion batteries, and the highest specific power of solar cell arrays in China.' These are their satisfactory answers.

The power controller is the 'brain' of the detector''s power system. In order to solve the problem of energy shortage and limited weight resources during the flight of the Chang''e-5 quadruple, the controller has undergone an upgrade from PCU to PCDU.

Xu Zefeng, head of Chang''e 5 power supply product technology, said, 'In response to the original low-integration density of circuit boards, we have conducted many tests and abandoned the in-line process that was commonly used in domestic satellite models at the time. This is the first time to lead the application of this technology in other subsequent models. At the same time, the innovative use of signal mother board, printed board current technology and bus bar optimization among the modules has achieved a high degree of integration of module cables. Greatly reducing the volume and weight.'Through the comparison with the Chang''e-3 product, it can be seen that the original frontal in-line process has been replaced with double-sided patch, and the circuit board integration density is greatly improved; the original densely packed The circuit board of the wires is now neatly distributed with a few clear lines, and the product density has been improved; and the number of single modules has been successfully reduced from the original 5 to 2, and the volume has reached the volume of the Chang''e-3 controller. 1/3 of it. For these technologies, more than 20 patents were authorized in the follow-up.

After taking full account of the mission time on the lunar surface and the working mode of the power supply products, in accordance with the overall plan, the developers optimized the energy design of the lander and riser assembly. Xu Zefeng said, 'The power products of the lander include solar battery arrays and power controllers, and the power products of the ascender include solar battery arrays, power controllers and lithium-ion batteries. Before separation, during the flight phase and the lunar phase, the landing The solar battery circuit of the solar cell assumes the responsibility of supplying power to the assembly; and when the assembly is separated during the lunar phase, the ascender quickly changes its role, and the solar battery circuit powers itself during the illuminated period. In the non-illuminated period, it lands. The device and the riser share a set of lithium-ion batteries, which provide power to the assembly.'

'In order to increase the power generation of the solar cell array, we set ourselves a goal to ensure that the patch area is maximized on the front of the solar cell array,' said Chen Cheng, the technical leader of the Chang''e 5 solar cell circuit.

'For the general satellite model, we only use a single size solar cell when designing the solar cell circuit. For Chang''e-5, we broke the conventional thinking and used multiple sizes of cells to mix the fabrics, so that the fabric efficiency reached 91% or more. This is 5%-10% higher than conventional products. At the same time, we must choose the solar cells with the most ×× rate. The photoelectric conversion efficiency of the solar cells of Chang''e-3 and Chang''e-4 are 28.6% and 30.84%, respectively. Chang''e-5 Achieved more than 31%'. Through unremitting efforts, the output power per unit area of the Chang''e-5 solar panel is not only at the time of product development, but even now, it is the highest level in China.

Specific energy is a major performance index of lithium-ion batteries. The higher the value, the more energy can be stored per unit volume or weight. At the beginning of the research, the maximum specific energy of domestic lithium-ion battery cells was 155Wh/kg, and the highest internationally was 165Wh/kg. In view of the short service life and high depth of discharge of Chang''e-5 lithium-ion battery products, the developers carefully analyzed the feasibility of technical indicators, consulted a large number of documents, and investigated the technical data of lithium battery companies, and formulated a solution. 'We selected lithium cobalt oxide cathode materials and graphite anode materials with higher specific energy, selected high molecular weight binder materials to reduce the amount of binder, and optimized the pole piece formula to increase the content of active materials', Chang''e No. 5 Lithium Said Wang Xiaorui, the designer in charge of ion battery. An understatement, behind a large number of process tests, new electrode materials, new material ratios, and completely different physical and chemical parameters from the past have caused great changes in the process of mixing powder, pulping and other processes. A footprint has verified every process in a down-to-earth manner. After 8 months of hard work, they increased the weight ratio of the battery to 195Wh/kg. This value is currently the highest value of specific energy for lithium-ion batteries used in aerospace.